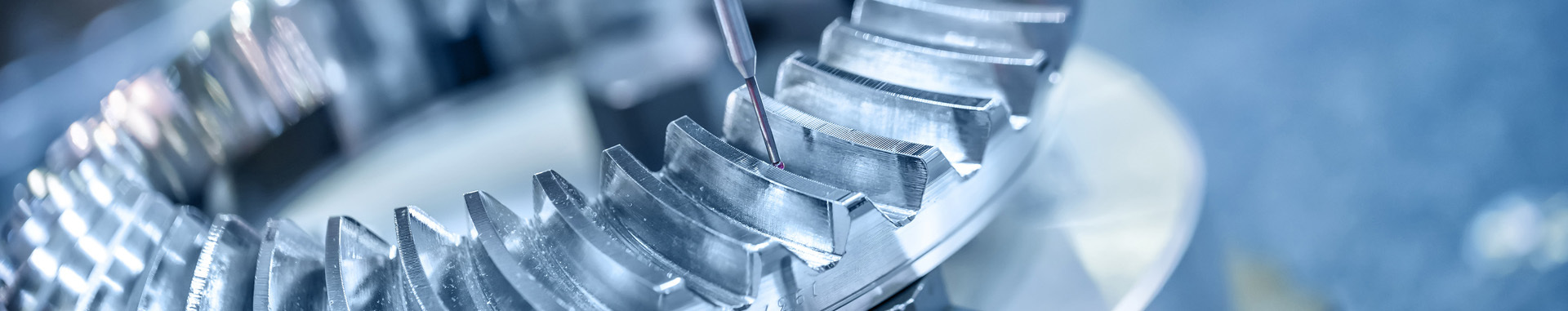

stainless steel metal stamping parts

Automotive plastic injection moulding designs offer manufacturers a great deal of flexibility, allowing them to produce parts in a wide range of shapes, sizes and textures.

- Information

Design Flexibility: Automotive plastic injection moulding designs offer manufacturers a great deal of flexibility, allowing them to produce parts in a wide range of shapes, sizes and textures. This flexibility makes it possible to produce parts that meet precise specifications, which is ideal for automotive manufacturers who need to accurately produce complex parts.

Durability: Automotive plastic injection moulding is a process that uses high pressure to inject molten plastic material into a mould to create parts. This process has been used for decades to create durable, robust parts for a variety of vehicles, from cars and trucks to boats and aircraft.

Precision: In recent years, automotive plastic injection moulding has gained popularity for its precision and versatility. Injection moulding can be used to create a variety of different parts, from large body panels to small interior trim pieces.