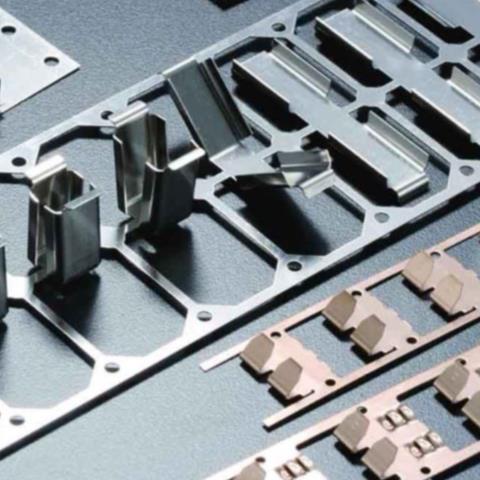

Communication Parts Stamping Production

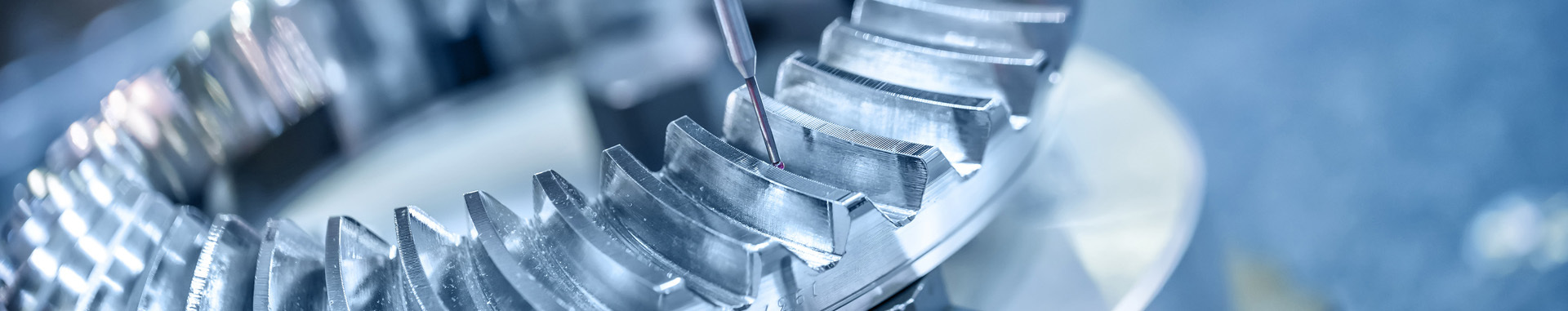

Metal stamping is popular with OEMs because it’s a fast and cost-effective production method for metal parts and components used in OEM machines and other finished goods. Metal stamping also produces highly repeatable parts with minimal waste, which means OEMs benefit from a lower cost per part on high-volume runs.

- Information

Communication parts stamping production rely on presses and molds to complete the process, its high productivity, easy to operate, easy to mechanize and automation. With ordinary presses for stamping processing, up to dozens of pieces per minute, with high-speed press production, up to hundreds or thousands of pieces per minute or more.

ZK is engaged in the production of communication precision stamping parts, specializing in providing solutions for precision stamping parts such as shield, antenna shrapnel, cell phone center plate, cell phone camera decorative parts steel piece and cell phone cartridge steel piece.

ZK offer prototype stamping, low-volume and high-volume metal stamping including progressive stamping and fabrication. We work with a very wide range of metal materials including stainless steel, carbon steel, copper, brass, aluminum, Ti and more.

ZK offers sheet metal stamping services in different fields:

Automotive

lithium batteries

Communications

Electronics

electrical appliances

Digital

Computers

mobile phones

Cameras

Lighting

medical instruments

Instruments

furniture

Contact ZK online for more information or submit an RFQ to get started on your project.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.