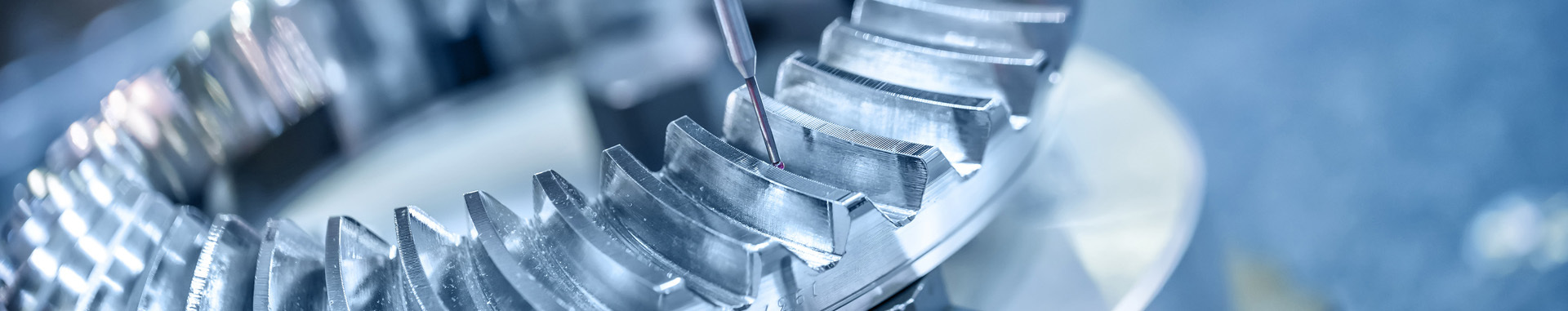

Medical Instrument Parts Stamping Production

Metal stamping is popular with OEMs because it’s a fast and cost-effective production method for metal parts and components used in OEM machines and other finished goods. Metal stamping also produces highly repeatable parts with minimal waste, which means OEMs benefit from a lower cost per part on high-volume runs.

- Information

The production process of medical instrument parts stamping production needs to go through a number of stages, such as material preparation, stamping processing, surface treatment, assembly and so on.

First of all, material preparation is the first step in the production of medical device stamping parts. The materials of medical device stamping parts are usually metal plates, which need to be cut, bent, cut and other processing to meet the requirements of stamping processing.

Secondly, stamping processing is the core link of medical device stamping parts production. Stamping processing needs to be carried out by equipment such as punching machines and molds to stamp metal sheets into the required shape, size and thickness. Stamping processing needs to take into account the hardness, toughness, strength and other factors of the material to ensure the quality and precision of the stamped parts.

Then, surface treatment is an important part of medical device stamping parts production. Surface treatment can be carried out by spraying, plating, polishing, etc. to improve the surface finish, corrosion resistance and aesthetics of the stamped parts.

Finally, assembly is the last step in the production of medical device stamped parts. Assembly involves assembling different stamped parts to form a complete medical device part. Assembly requires consideration of factors such as the precision, size and fit of the parts to ensure the reliability and stability of the medical device.

Translated with www.DeepL.com/Translator (free version)

ZK offers sheet metal stamping services in different fields:

Automotive

lithium batteries

Communications

Electronics

electrical appliances

Digital

Computers

mobile phones

Cameras

Lighting

medical instruments

Instruments

furniture

Contact ZK online for more information or submit an RFQ to get started on your project.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.