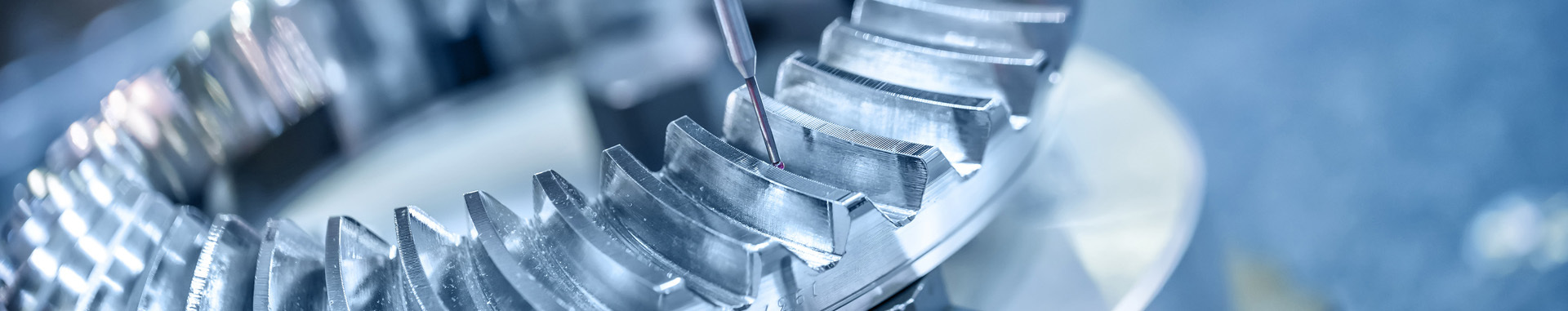

Metal Part Stamping Production

Metal stamping is popular with OEMs because it’s a fast and cost-effective production method for metal parts and components used in OEM machines and other finished goods. Metal stamping also produces highly repeatable parts with minimal waste, which means OEMs benefit from a lower cost per part on high-volume runs.

- Information

ZK offers sheet metal stamping services in different fields:

Automotive

lithium batteries

Communications

Electronics

electrical appliances

Digital

Computers

mobile phones

Cameras

Lighting

medical instruments

Instruments

furniture

ZK is a leader in producing stamped metal parts for OEMs (original equipment manufacturers). With automatic stamping equipment, an in-house tool shop and IATF16949:2016 and ISO9001:2015quality management system certification, we can handle your OEM stamping project with guaranteed precision and repetitive accuracy.

Since 2016 ZK has been providing custom stamping parts for OEMs in a range of industries. We can manufacture metal stamping up to 6mm thickness and achieve tight dimensional tolerances of +/-0.03mm. Your parts will be delivered on time and production ready, meeting the needs of your schedule.

ZK offer prototype stamping, low-volume and high-volume metal stamping including progressive stamping and fabrication. We work with a very wide range of metal materials including stainless steel, carbon steel, copper, brass, aluminum, Ti and more.

ZK offers sheet metal stamping services in different fields:

Automotive

lithium batteries

Communications

Electronics

electrical appliances

Digital

Computers

mobile phones

Cameras

Lighting

medical instruments

Instruments

furniture

Contact ZK online for more information or submit an RFQ to get started on your project.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.