In 2014, Dongguan ZhongKai Precision Metals Technology Limited was established.

In 2015, we planned to build a factory located in Changping town, Dongguan city, covering an area of about 3500 square meters, introduce talents and equipment, and conduct trial operation.

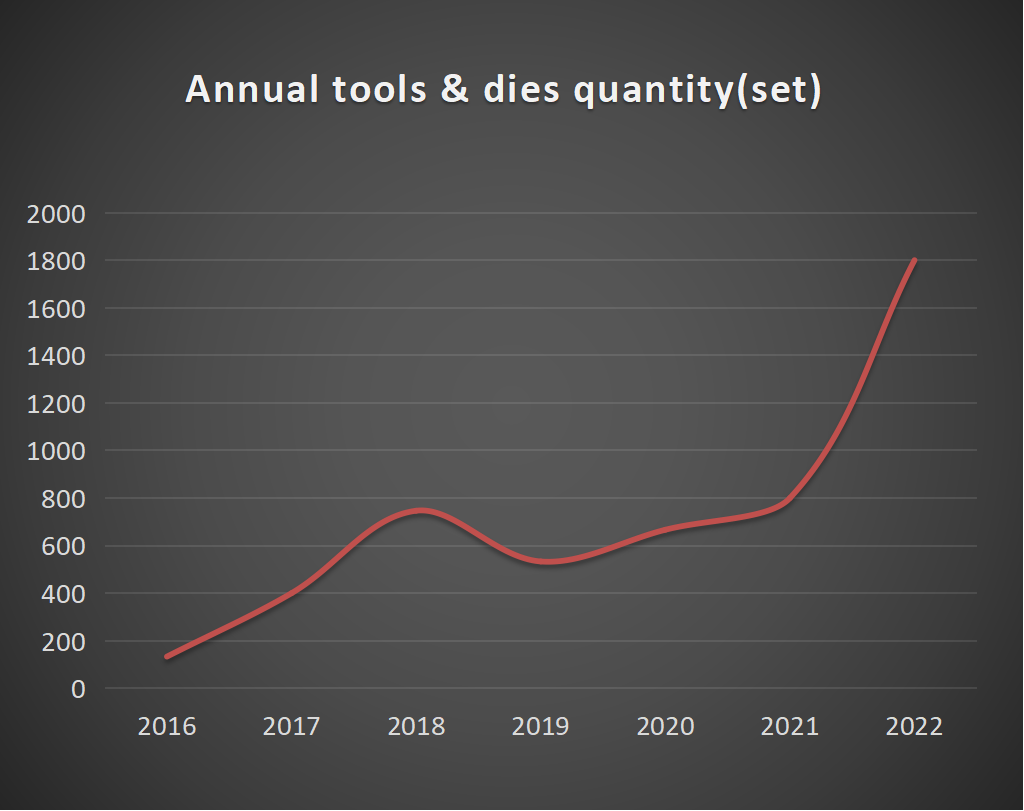

In 2016, mainly to produce precision metal tool and die and obtained ISO9001:2015 quality management system certification.

In 2017, become a precision metal tool and die supplier of of BYD, Midea, Gestamp and other powerful enterprises, with annual sales exceeding USD 450million.

In 2018, ZK continued to develop, and expanded the scale of production, put in several sets of high-precision processing equipment, such as Seibu Slow wire EDM and Sodick Slow wire EDM, speed up precision metal tool and die production efficiency, sales volume reached 2 times of 2017.

In 2019, ZK was affected by peripheral markets and the performance fluctuated slightly, but ZK persevered and continuously improved the production technology, and passed the IATF 16949:2016 quality management system certification in the same year.

In 2020, ZK implemented the performance management system to improve production efficiency, Finally, precision metal tool and die is restored to the production level of 2018

In 2021, sales increased steadily and the company introduced 25 technical talents.

In 2022, automotive precision metal tool and die orders increased rapidly, ZK established 9000 square meters factory, invested several large manufacturing equipment, and introduced about 100 technical talents.

Create more value for users and partners

Creating value is the survival instinct of ZK. We are not only committed to creating value for users, but also strive to create value for society, for employees, for upstream and downstream partners and stakeholders in the industry.

Let each set of tool because of our manufacturing more valuable

As the core industry, ZK is from the tool manufacturing stage to jump up in the pursuit of quality, speed, efficiency at the same time pay more attention to product value shaping.

OUR CAPABILITES

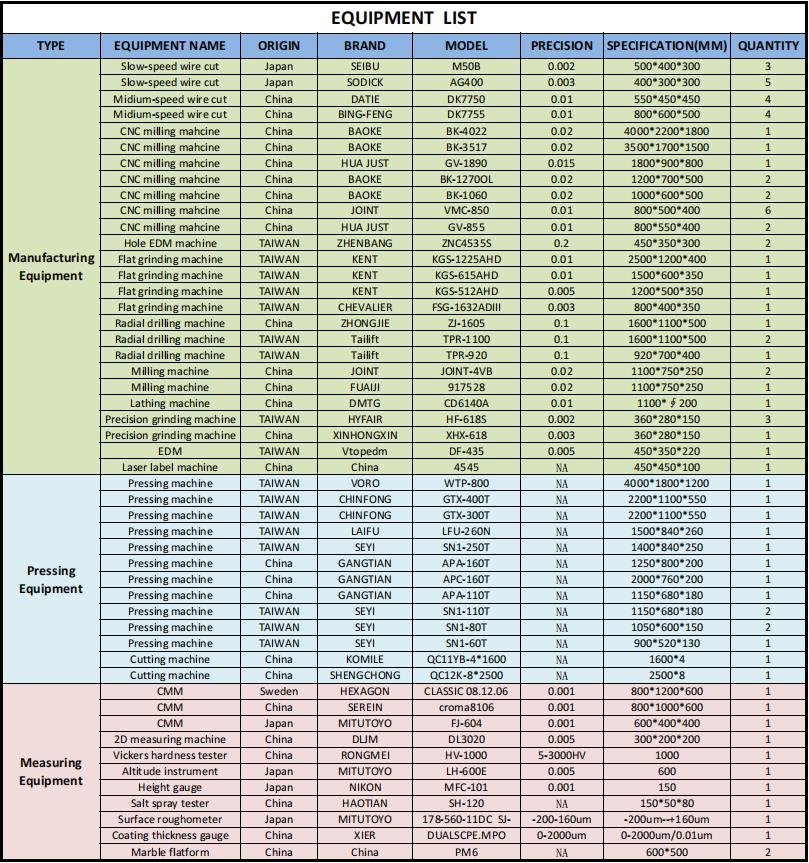

ZK have a complete to order follow up process, can provide customers with high quality follow up service.

TOOL DESIGN & DEVELOPMENT

ZK have a team of 60 engineers with rich experience in automotive die design. With passion, responsibility and quality concept.

PRECISTION TOOLS MANUFACTURING

ZK have a professional engineering and manufacturing team,Specialize in

precision progressive die,

multi-stations transfer die,

deep drawing die,

other automotive stamping die ,

non-standard automation equipment design and manufacturing,

precision parts processing,

metal product stamping production.

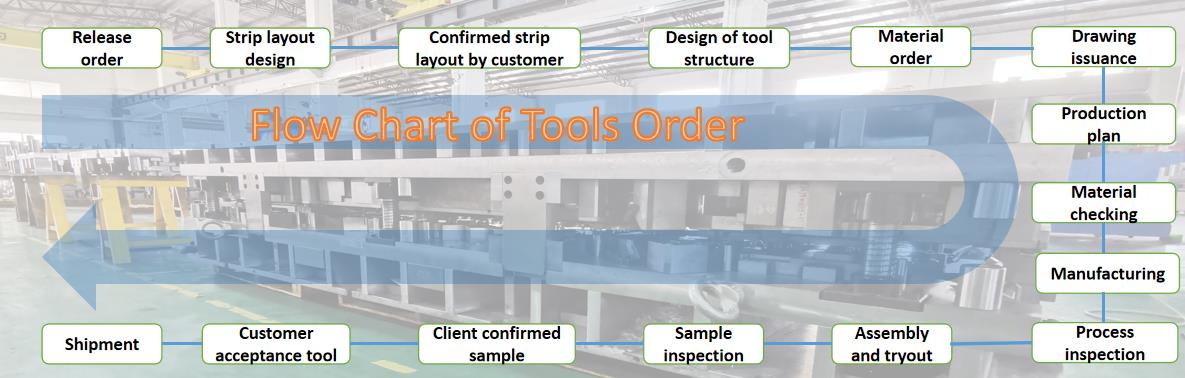

EQUIPMENTS

ZK has sufficient equipment to serve our customers.

QUALITY POLICY

————Quality First, Never Compromise

ZK is committed to the delivery of safe and quality products to customers.

Meet all customer’s requirements.Customer problem solved.

Communicate this Quality policy to all employees.

Continually improve our quality performance.

COMPANY PROSPECTS

ZK through serious quality control of tools & dies and reasonable production arrangement, we have saved a lot of costs for customers and accelerated the development schedule of the project, winning customers' trust in our company and continuously improving the company's performance.

Factory Show

-

![Quality Assurance]()

Our company has passed the certification of ISO9001 quality management system and the certification of IATF 16949 quality management system of auto industry. To assure the quality of the products for our yalued customers.

-

![Stamping Equipment]()

We have 800T、400T、300T、250T、160T、110T、80T、60T etc. press machine for tryout, apply for different size of molds commissioning and maintenance.

-

![Tool Assembly & Tunning]()

We have an experienced assembling team, most of themhave been working in the tooling field over 5 to 20 years. By strictly following up procedures and work instructions to keep tool assembly accuracy and quality assurance.

-

![Processing CNC]()

In order to meet the needs of customers, the companyintroduced different models of CNC equipment, and payattention to the training of high-quality professional and technical personnel.

-

![Engineering Technology]()

ZhongKai have experienced team ofengineers,including 30 Design Engineers.expert to use design software of UG-NX7.5,Catia V5,Auto-CAD, Pro E,Solid Works,Mastercam etc, which couldeffectively control the processing data,For the critical parts will use Dynatormand Autoform software to apply the simulation analysis.

-

![Processing Wedm]()

Committed to creating a comprehensive and stable productivity, in order to be in an invincible positionin the increasingly competitive market environment, we continue to introduce high-precision advanced wire cutting processing equipment from abroad, to provide customers with lasting high-quality, eficient processing needs, to meet customers' various mold requirements to provide the best solution.