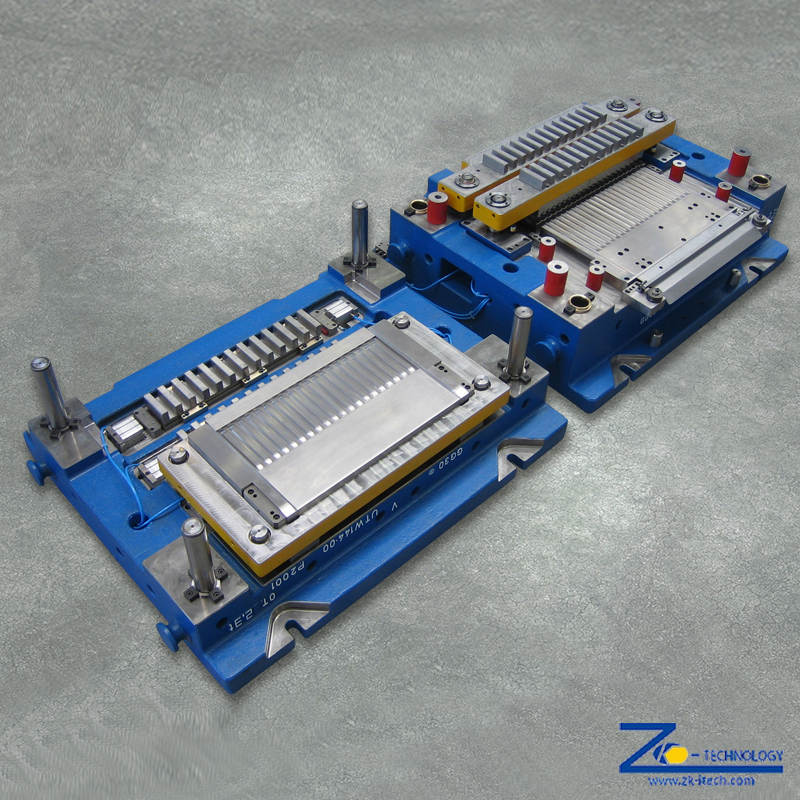

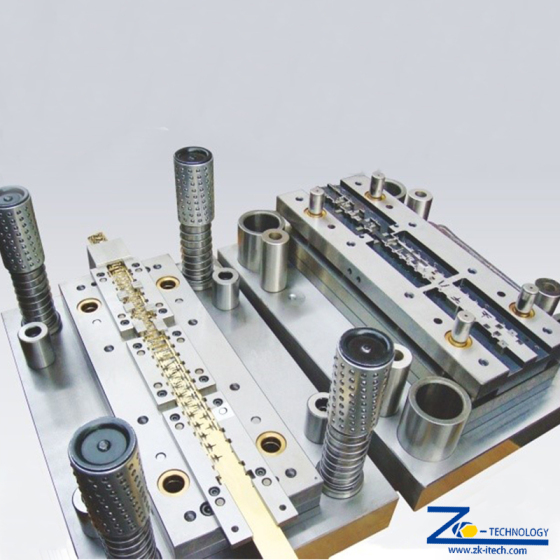

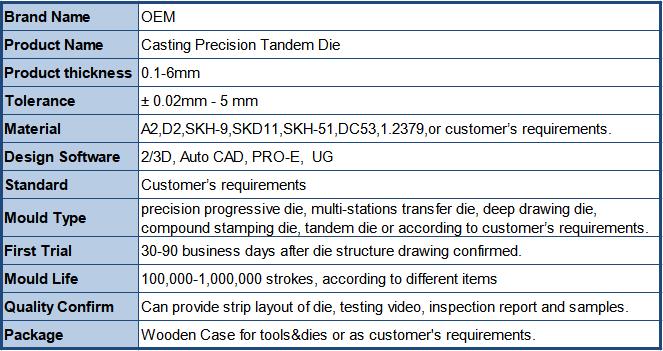

Casting Precision Tandem Die

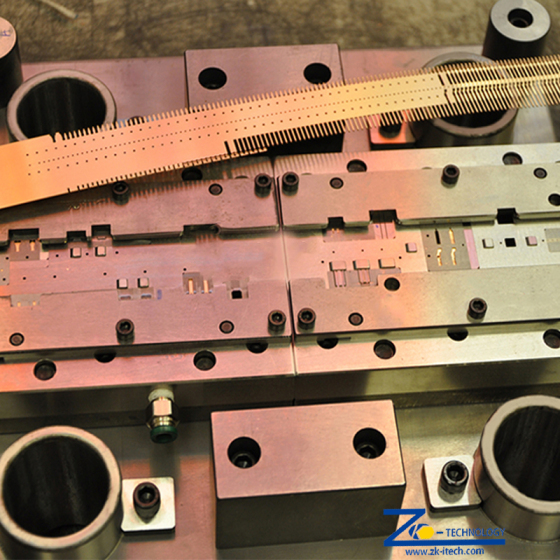

Tandem die is a stamping die that can complete multiple processes at the same time, which solves the problem of low efficiency and high processing cost that the existing stamping die can only process one shape.

- Information

CATEGORIES: MACHINING, TOOL & DIE

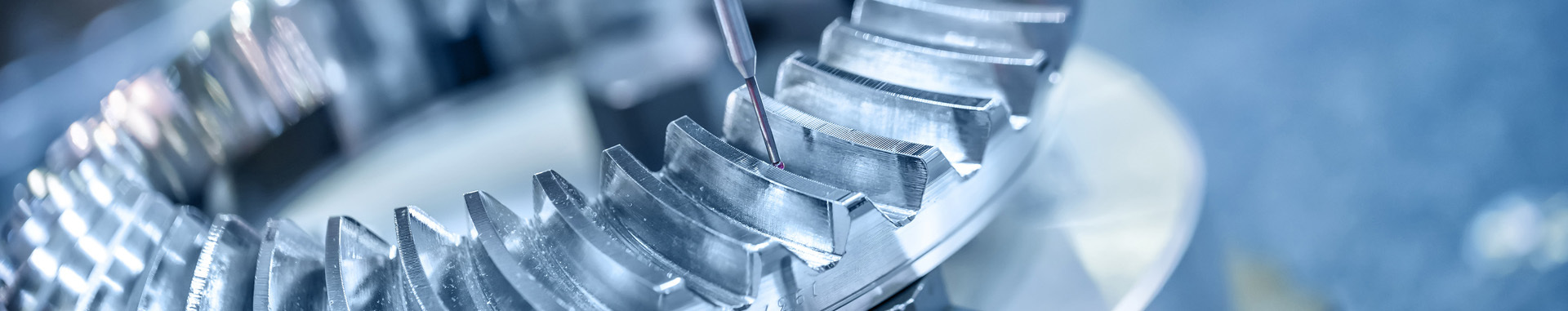

A tool made by a tool and die maker probably had a hand in producing almost everything around you. But what exactly is a tool and die maker?

Ultimately, a tool and die maker is a specialized machinist. More specifically, they work with machinists to keep manufacturing machines running smoothly. Basically, toolmakers build the tools and fixtures, while machinists focus on production machine work, assembly, and fitting. Machinists essentially have to lay out metal stock, set up and operate machine tools, fit and assemble parts to make and repair dies, cut tools, jigs, gauges, etc …

TOOLS AND DIES: WHAT’S THE DIFFERENCE?

What is the difference between a tool and a die? In most cases, machinists use these two terms interchangeably. However, there is a slight difference between these two concepts.

Dies are a subset of tools which means that all dies are tools, but not all tools are dies. For instance, in the metal stamping process, a tool can be almost any mechanical device that cuts, forms, supports, or molds metals. Considering this, jigs and fixtures are tools. Dies, on the other hand, are only those tools that functionally change the shape of the metal.

Also, a die has a particular focus. It is a machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Similar to molds, dies are generally customized depending on their purpose in manufacturing. There are numerous products made with dies, ranging from simple office supplies like paper clips to more complex pieces used in airplanes. On the other hand, tooling (or machine tooling) is the process of obtaining specialized components and machines needed for the full-scale manufacturing process.

Tools and dies are fundamental to ensuring durable goods during manufacturing production. Die-casting yields major cost savings in high-volume production processes, making it invaluable to businesses. There are many industries served by tools, dies, and machinists. Without the tool and die process, manufacturing and production companies around the world would be next to impossible.

Our advantages

Professional development and design ability

We have an experienced research and development team, and complex, difficult molds can be rapid molding and design accurately.

Quality assurance

The company has advanced testing equipment and strictly implements ISO9001 and IATF 16949 certification.It is possible to eliminate any quality problems in production.

Accurate delivery

We have the first-class advanced processing equipment, effectively ensure the rapid response and efficient service.

Business introduction

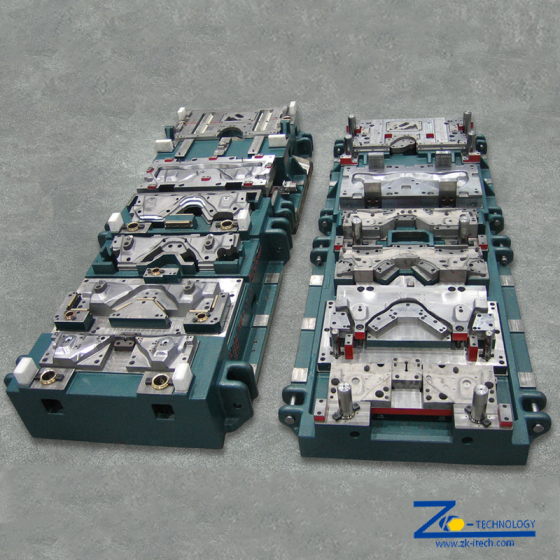

ZK specializes in designing and producing of various metal stamping tooling, and is good at producing the precision metal stamping parts.

Our company is developed steadily since its establishment with the hard work of the professional designers and all the other staffs. Nowadays, we are able to produce different kinds of hardware stamping tooling and auto-parts stamping tooling, like progressive tooling, continuous drawing tooling, machine-hand transfer tooling, etc. We are well experienced in producing tooling for stamping machines' capacity from 60 Tons till 800Tons.

At present we are able to undertake the batches of tooling development business, especially plenty experience and mature technology in designing and producing auto-parts and electric appliance parts. We will provide series service in tooling designing, developing, producing and parts production. In order to meet the developing requirements of our customers, we import the advanced machinery and the qualified technicians timely.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.