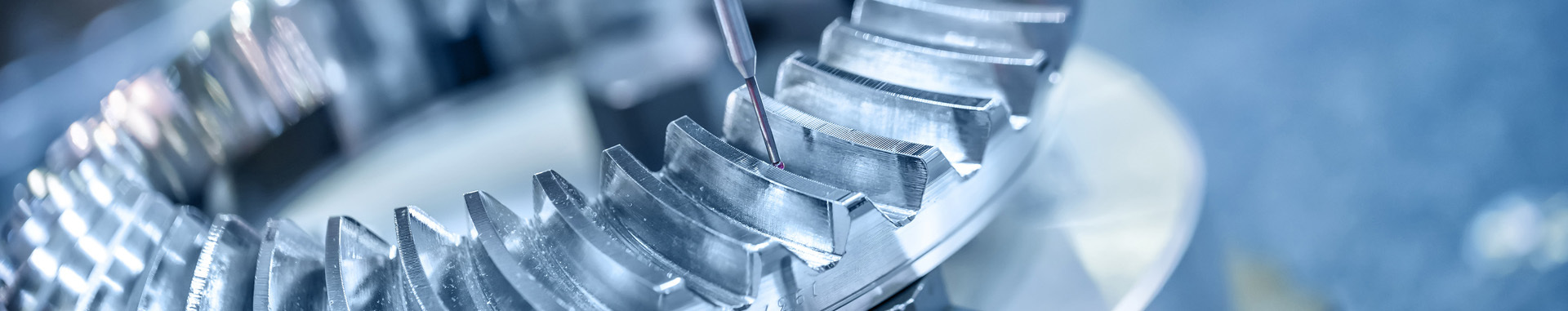

CNC Precision Accessories Machining

We offer rapid prototyping, small-batch machining, and high-volume production, with all orders serviced by ZK from end to end. Our fast CNC machining capabilities include services for metals and plastics and flexible production and shipping options to meet you at the perfect price and product development stage.

- Information

What is CNC Precision Accessories Machining?

CNC or Computer Numerical Control machining is a widely used manufacturing process that uses automated, high-speed cutting tools to machine metal or plastic materials into a designed pattern. Standard CNC machines include three-, four- and five-axis mills, lathes and routers. CNC machines cut parts in different ways - the workpiece may stay in place while the tool moves, the tool may stay in place while the workpiece rotates and moves, or the tool and workpiece may move together.

When operating a CNC machine, a skilled machinist programs the tool paths based on the geometry of the final part to be machined. The part geometry information is provided by a CAD (Computer Aided Design) model. CNC machines can cut virtually any metal alloy and hard plastic with high accuracy and repeatability, making custom-machined parts suitable for virtually all industries, including aerospace, medical, robotics, electronics and industrial.

ZK measures the parts to make sure that they meet the tolerance range requirements, and then delivers the parts to the customer by shipping via sea/land/air depending on the different packaging methods required by the different customers.