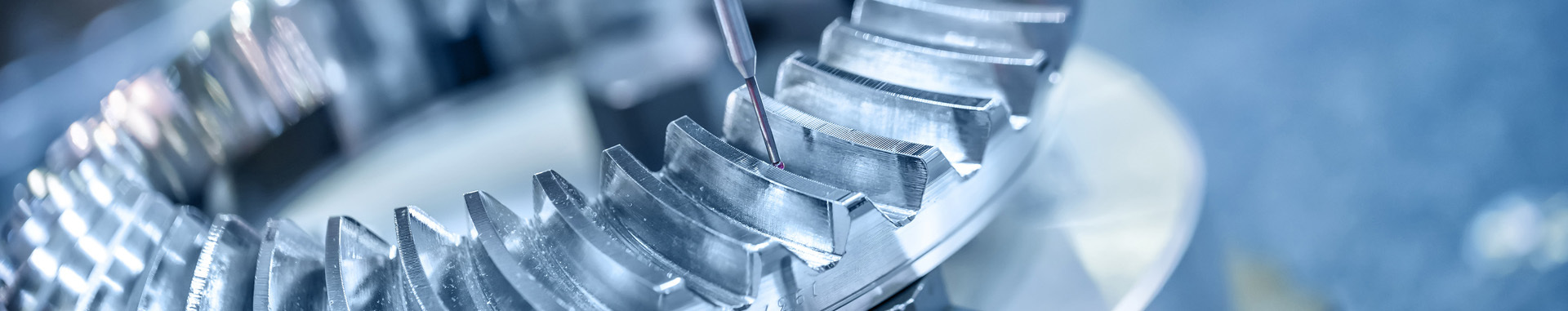

Mould Mold Tool Die Insert Manufacture

The term tool insert is very familiar and frequently used in the tool industry. Inserts are mainly used to insert various irregular parts in irregular tools. Good quality inserts can be used to fill the tool plate or fix the tool plate space. In fact, it is to help the tool to repair some defects

- Information

Why are inserts used in tools & dies & mould & molds ?

The term tool insert is very familiar and often used in the tooling industry. Inserts are primarily used to insert various irregular parts into irregular tools. A quality insert can be used to fill the tool plate or to fix the tool plate space. In fact, it is used to help the tool fix certain defects. So, why do tools use blades?

1, convenient to modify the tool

Tool need to be modified after a period of production, so you can go ahead and add blades to the place where you modify the knives. The blade can be replaced later, and even a few spare parts of the blade can be made for replacement when the tool is made, which makes it convenient to modify the tool.

2, convenient tool processing

ZK knows that some deep grooves and holes on the tool are difficult to process and polish, and the design of inserts in these places can reduce the processing difficulty.

3, increase the service life of the tool

Generally speaking, inserts are designed in places where moulds are easily damaged. Once the inserts are damaged, they can be replaced, thus extending the service life of the mould.

The use of mould inserts plays an important role in moulds, which not only reduces the damage rate of moulds, but also improves product quality and reduces defective products. With the application of tool inserts, ZK can more easily modify or manufacture tools at any time, saving more cost for customers.

ZK can provide customers with customized services for replacement parts on tools, as follows:

Male die, female die, draw ring, feature die, upper die, lower die, dowel pin, guide pin, pilot pin, lifter pin, spare plate, tool insert, punch holder insert, upper stripper insert, lower plate insert, piercing punch, blanking punch, trimming punch, lance punch, round piercing punch, scrap cutter, special shape punch, bending punch, forming punch, drawing punch, deburring punch, groove punch, stamped punch, guide plate, located block, sliding block, stripper plate, holder block, guide pillars, guide pin, guide bushes, logo stamp.

ZK offers different coatings for inserts according to customer requirements.

1.TD Coating Centre (TDCC) is synonymous with delivering high precision, high performance tools and machine parts that increase productivity, reduce downtime and maximise part life, and ZK achieves this through the right metallurgical combinations, the right selection of base metals, appropriate heat treatments and surface engineering, and high quality part manufacture.

The coatings and surface treatments we are involved with include Thermal Diffusion (TD) coatings, which have been shown to outperform many competing coatings, various PVD coatings including DLC, and surface treatments such as Controlled Nitriding, Boriding, etc.

Moulds and parts (coated or uncoated) are manufactured from a variety of steels, tool steels, special PM tool steels, carbide or tungsten alloys that are precision ground (not just machined.) ZK pays attention to the overall design of the part, including the correct tolerances, to ensure a first time fit and to maximise the life of the part, and has many years of experience in this area. It's all about getting the highest performance out of the part. zk is the one-stop solution for ultimate performance!

2. Physical Vapour Deposition or PVD coatings have made their presence felt in the manufacturing industry primarily through the cutting tool market. Whilst this market remains the largest application area for these coatings, their excellent properties of high hardness, low coefficient of friction and good wear resistance can also be used in many other tool and component related applications.

ZK offers the following standard types of PVD coatings:

Titanium Nitride (TiN)

Titanium Carbonitride (TiCN)

Titanium Aluminium Nitride (TiAlN)

Titanium Aluminium Nitride (TiAlCN)" aka Variantic

Chromium Nitride (CrN)

Aluminium Chromium Nitride (AlCrN - aka AlCRONA)

Chromium Carbide Top Coat (CrC)

Diamond-Like Carbon (DLC) - available in ultra-low friction, high hardness coatings

YDLC - multi-layer DLC coatings for improved adhesion

The above coatings are also available as double coatings for applications with higher demands on surface loading and fatigue life.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.