Do you know several ways of strip for stamping progressive die?

2024-06-28 08:50Function of progressive tools and dies strip:

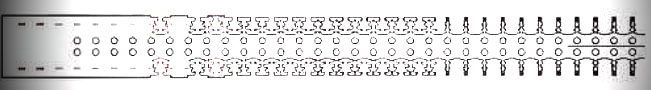

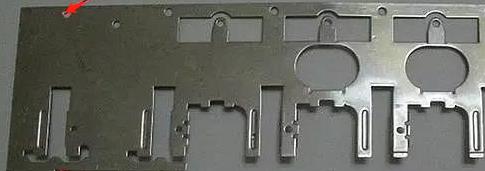

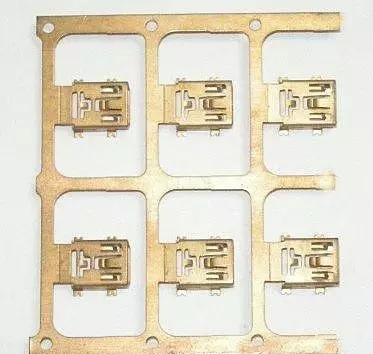

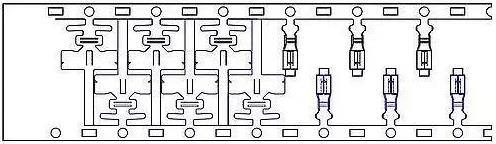

Progressive die is the stamping process (station) required to complete the product, arranged in the same set of die for punching. The material used by progressive die is coil material, and the material is sent equidistant to each separate station in the die for stamping processing, and the product is completed to the final station. In the progressive die will be material processing: punching, separation, bending... Etc., and link each station semi-finished materials, known as the strip. Generally, the material carrying area in the mold and the part linking the semi-finished product to the finished product of each station are collectively referred to as the strip. Experienced tool designers can know the design method of this set of mold by observing a strip.

Composition of progressive die strip:

The strip is composed of a certain hole and a safe width of the material, the main function of the positioning hole is to make the material can be sent equidistant to each station for stamping processing, to ensure the accuracy of stamping processing, and the edge width of the remaining material is mainly used as a link and transfer of the station of the semi-finished products, the semi-finished products will be connected and transferred to the next station for stamping processing.

1. Positioning hole diameter:

∮ (∮2.0mm), ∮2.5mm (∮2.5mm), ∮3.0mm (∮2.5mm)... But now the stamping parts are getting smaller and smaller, and the feeding pitch is getting smaller and smaller. The existing positioning hole has been set to 0.7mm.

2. Set the width of the strip:

The width of the material belt mainly lies in the stable connection and transmission of the semi-finished products to the stamping station. General common strip width set ≧3.0mm, can also be designed according to the actual demand.

Progressive die strip mode and application:

1.Single side tape type

Widely used in connector terminals, small stamping parts.

2.Double side tape type

Mainly suitable for more complex characteristics, high bending height, wide material width, easy to deformation in the process of strip transmission, large stamping parts, etc., can not rely on a single side of the strip transmission, can choose the double side of the material belt type.

3.Double tape type

Double tape type is mainly from the evolution of double side strip type, the purpose is also to save material design, when the use of double side strip, there are two side strip to carry out the material, such as adding a side by side strip, can save a strip. This design can also produce different stamping products, only the stamping products need to be at the same time have the same demand quantity. This is not the case when the same stamping products are arranged.

4.Double independent tape type

Double independent tape type is generally designed to save material, and the two stamping products are inserted and arranged to achieve the purpose of saving materials. Two different stamping products can also be arranged on one side at the same time for stamping, such as used in stamping different products, the stamping products need to have the same demand at the same time. This is not the case when the same stamping products are arranged.

5.Middle tape type

It is mainly suitable for products with low size requirements and low stamping accuracy. Using this design method can generally improve the utilization rate of materials, but the relative stamping accuracy and stamping speed are poor. It is generally not recommended to use this design mode.