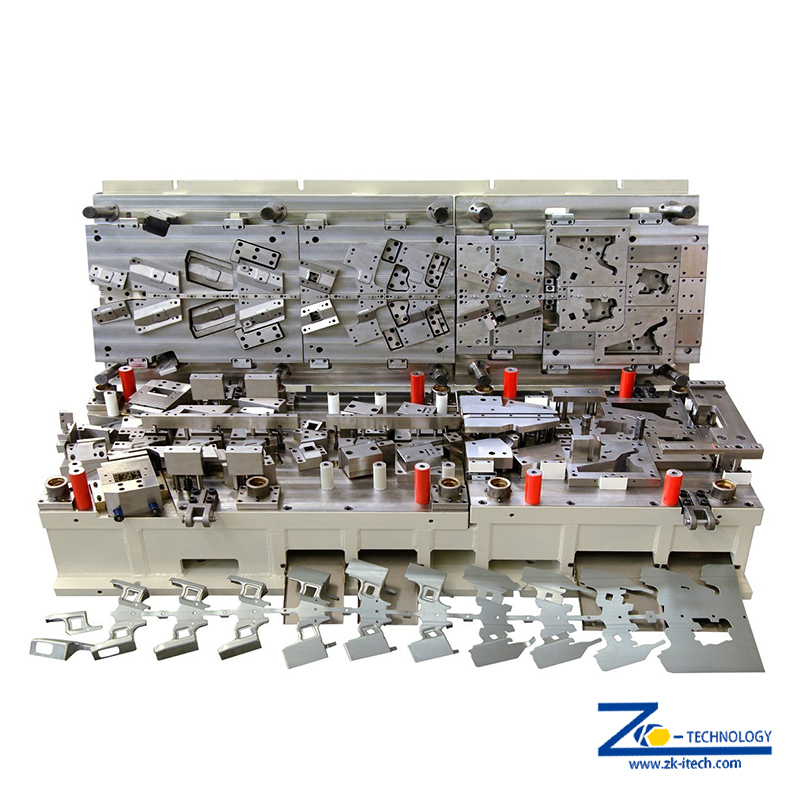

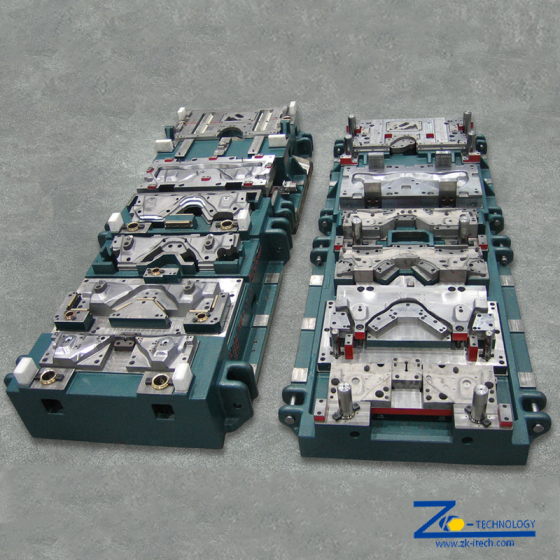

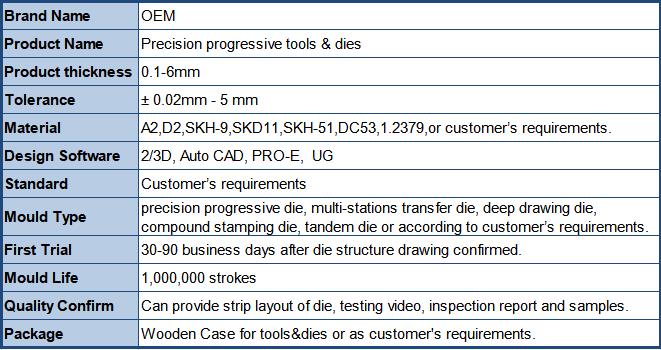

OEM Precision Progressive Stamping Die

OEM Precision Progressive Stamping Die describes metal forming processes that require custom tooling and techniques to produce parts specified by the customer. A wide range of industries and applications employ custom stamping processes to meet high-volume production needs and ensure all parts meet exact specifications.

- Information

Metal stamping is popular with OEMs because it’s a fast and cost-effective production method for metal parts and components used in OEM machines and other finished goods. Metal stamping also produces highly repeatable parts with minimal waste, which means OEMs benefit from a lower cost per part on high-volume runs.

ZK offers comprehensive metal stamping services including:

Custom draw stamping

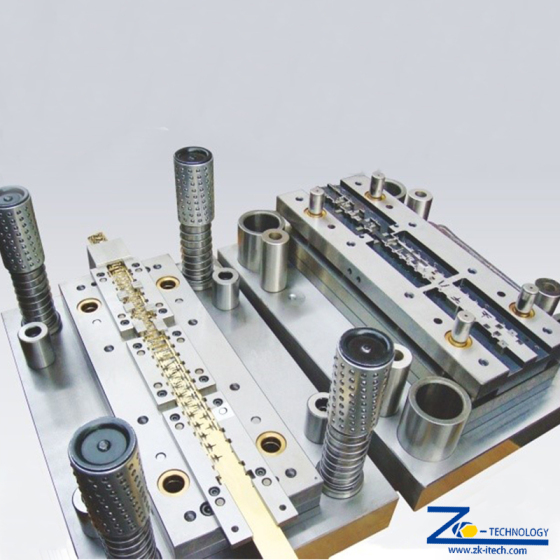

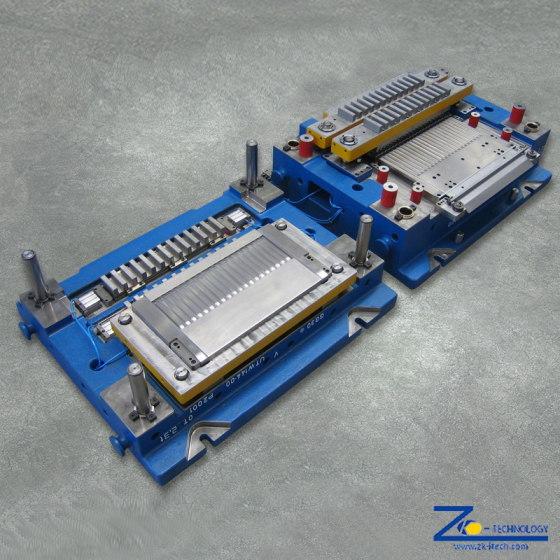

Progressive die stamping

Compound die stamping

Fine blanking

Additional OEM capabilities include:

Forming & shaping

Metal fabrication

Our value-adding secondary services allow OEMs to source as much of their part manufacturing needs as possible from a single supplier, providing greater control and efficiency.

Our advantages

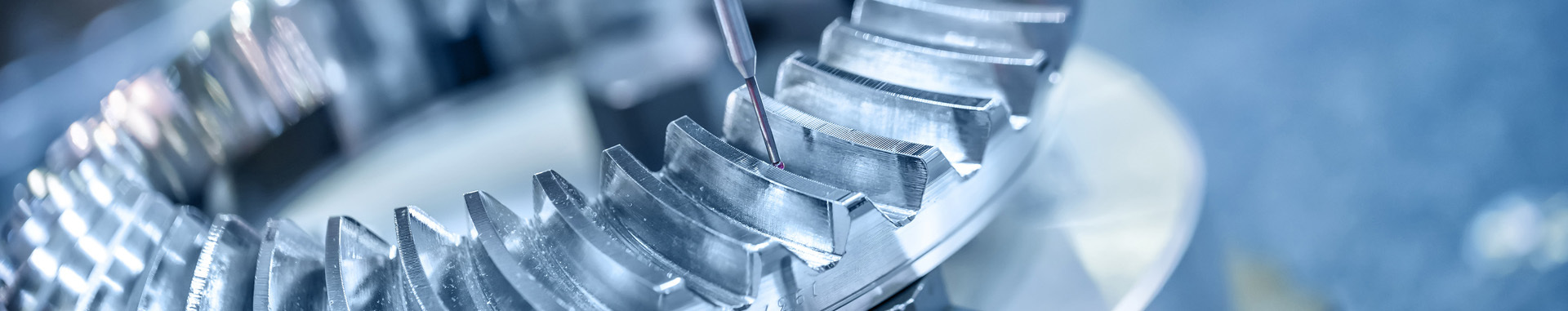

Professional development and design ability

We have an experienced research and development team, and complex, difficult molds can be rapid molding and design accurately.

Quality assurance

The company has advanced testing equipment and strictly implements ISO9001 and IATF 16949 certification.It is possible to eliminate any quality problems in production.

Accurate delivery

We have the first-class advanced processing equipment, effectively ensure the rapid response and efficient service.

Business introduction

ZK specializes in designing and producing of various metal stamping tooling, and is good at producing the precision metal stamping parts.

Our company is developed steadily since its establishment with the hard work of the professional designers and all the other staffs. Nowadays, we are able to produce different kinds of hardware stamping tooling and auto-parts stamping tooling, like progressive tooling, continuous drawing tooling, machine-hand transfer tooling, etc. We are well experienced in producing tooling for stamping machines' capacity from 60 Tons till 800Tons.

At present we are able to undertake the batches of tooling development business, especially plenty experience and mature technology in designing and producing auto-parts and electric appliance parts. We will provide series service in tooling designing, developing, producing and parts production. In order to meet the developing requirements of our customers, we import the advanced machinery and the qualified technicians timely.

ZK through measure the parts to determine that the parts meet the tolerance range required, and then deliver them to customers by sea/land/air and other means of transportation according to the different packaging methods required by different customers.